Engine House

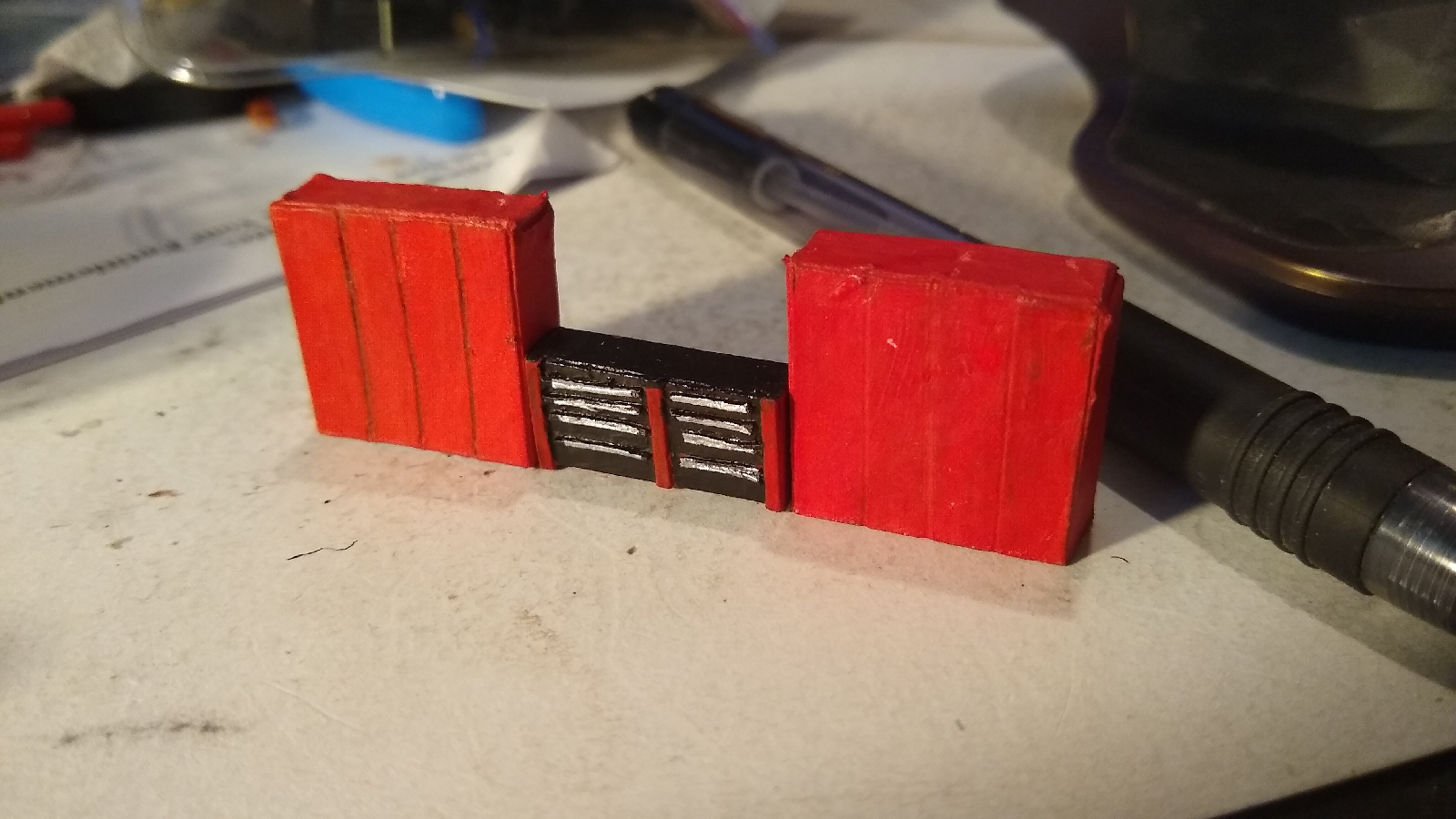

I'm contemplating making a small switching layout (or this may end up on my Vine and Branches Layout) and thought it would be nice to have a small engine house to park the engine and keep it out of the weather. The Pike's Stuff Small Engine House was tempting but larger than I wanted and I wanted to scratch build and practice my styrene techniques.

Here are the self imposed build parameters I'm working within

- Build from one 15x19 For Sale sign

- House a Walthers Plymouth ML-8 or BLI Plymouth W-Series 35-Ton Switcher

I've been very tempted to add 3D printed detail parts but I want to make something that others can replicate. If there is enough interest I may build another version that is detailed out with my SLA 3d printer.

I started by using the basic size of the Pike's Stuff small engine house as a guide and then went from there. The size is 30'x60' feet which I thought was a little long for my needs so I went 30'x41'. After cutting out the walls I decided to build some I-beam to support the walls and roof. The I-beams are 1 foot wide. The building is 24' tall so I cut some 3' wide strips for the center of the I-beam by 25' long. Next I split the strip in half so it was 2' at one end and 1' at the other. I'll include more details of how I assembled these later.

For the base I started with building some code 83 track on PCB and wood ties. I cut the track long enough that I can place my largest diesel engine on it as I might use it as my programming track. I measured the thickness and then subtracted the thickness of 1 sheet of styrene and cut some strips that wide. Next I drew out the outline of the building on a larger piece of styrene and started gluing the strips down for the concrete floor of the building.

(More to come)

Comments

Post a Comment